How we Make Stuff, Continued: Wax Model, CAD Model, or Hand Fabrication?

As I briefly discussed in my previous blog, Cecile Raley Designs primarily designs jewelry using CAD. This is probably the most cost-effective way to produce a jewelry design, but it’s by no means the only way. Let's first have a look at the other two ways of making a piece of jewelry: wax model and hand fabrication, to see the advantages and drawbacks of each.

This blog is co-authored with Inken Krause, owner of Enhoerning Jewelry - Most of Inken's own jewelry is hand fabricated from scratch, and she uses hand carved wax for certain custom orders, especially for antique inspired reproduction pieces.

The main advantages of wax carving are being able to carve almost anything, being able to create designs of varying complexity, and being able to produce very organic designs. The disadvantage is the cost of labor. A wax carving can take a couple of hours up to a couple of days!

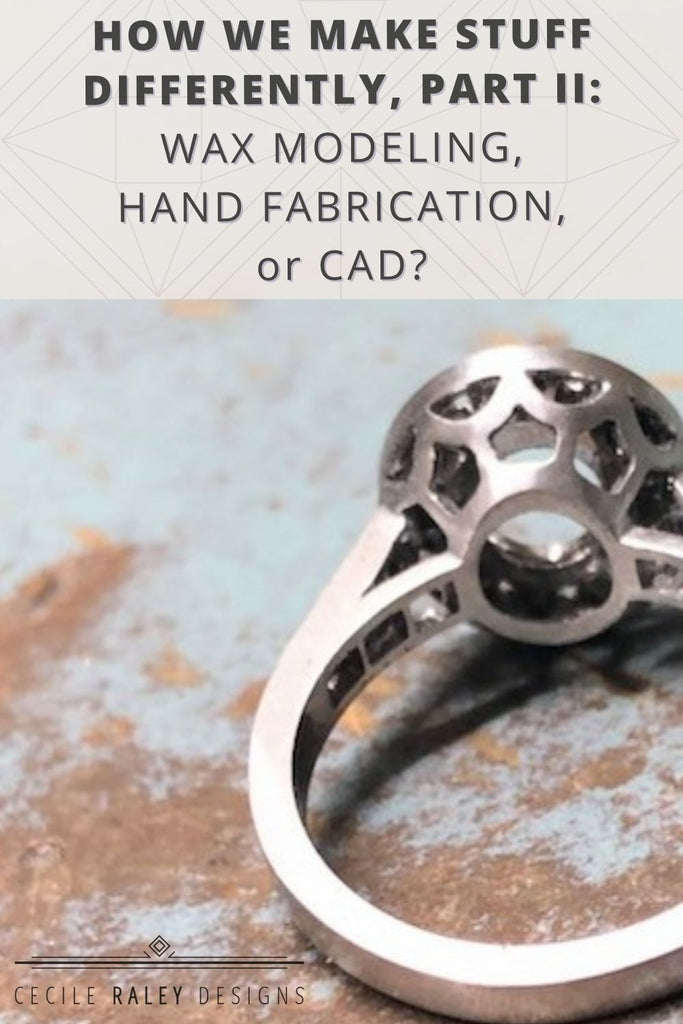

Wax Carved Ring with Wire Open Work And Piercing by Enhoerning Jewelry: "Wire-based jewelry styles styles can be emulated in CAD or with hand-carved wax, but they tend to come out less clean, and sometimes the "wires" will be a little squarish and not perfectly round." Inken Krause

Hand Fabrication: this process refers to the actual metalsmithing of a piece, e.g. cutting and sawing sheet metal, stretching wire or rolling out metal if needed, and then soldering everything together. No casting will be required, except perhaps if one wants to make a mold of the finished piece to recast for later usage or to make more pieces of that same exact design.

An advantage of hand fabrication is achieving a certain level of detail that you can’t get with CAD. One can right away work in mixed metals by just soldering together any metals one likes. Individual parts can be cleaned and fine-tuned before they are assembled, and they can be remade as well if there’s a mistake. Metalsmithing lends itself to making high-end and intricate pieces, though not to any kind of organic design as the basic shapes are flat metals and various shapes of wire (round, flat half-round). But hand fabrication is very time-consuming and therein also lies the drawback; it can be very expensive. A ring with many parts can take a week in labor instead of a few hours or a day or two with wax carving. Finally, the “bench work” as we call it in the trade, requires enormous amounts of skill and that too costs money. But the finished look is often stunning in its detail and well worth the price for a fine quality piece for an extraordinary gem.

CAD Modeling: making the model on the computer with the help of a CAD program like Rhino. CAD modeling was originally developed for mathematical design, but as jewelry design involves just that (i.e. a lot of geometry), adapting these programs for jewelry design was a logical step. CAD programs are difficult to use at first (and expensive to buy), and just like with the two other methods of fabrication mentioned above, it also requires a good understanding of how jewelry is made. Shrinkage in casting has to be calculated; prong placement, basket, and gallery designs need to be such that they don’t break in casting, they allow for wear and tear, they allow for the setter to have enough metal to work with (i.e. prong thickness and length, depth of basket), and that they can be properly cleaned after casting, to remove the gridlines of the printer – an issue that doesn’t arise in hand fabrication, as one can clean and polish off at any step during assembly.

An advantage of CAD modeling is certainly the price because an extremely simple model (say a wedding band) can be done in just minutes, up to a couple of hours for something complicated, and maybe a day for an extremely elaborate and organic design. Changes can be simple and don’t involve and waste of metal or wax. Changes require deleting a lot of steps or just a few, just like deleting a paragraph in a letter or scrapping the entire thing. Also, a jeweler can provide a file for a model meant for a different stone size and have the CAD designer make a model based on the original specs, thereby creating a new model that is exactly to specs. (When you look at the Stuller catalog and click on the different gem sizes and shapes to see an image, you are actually calling up an image of a new CAD file made for that gem size and shape in the same design).

Also, a CAD model can be rendered for viewing, meaning a “rendering” software is used to give the CAD model a finished look. Rendering software comes with colors to represent gems and metal, metal finishes (like brushed or polished), and other tools that provide the client a sneak peek of the finished piece, allowing for easier adjustments and modifications based on the rendering.

A disadvantage of CAD modeling is that because the process is mathematical/geometrical, i.e. by working out the geometry of a quarter of a ring top and then replicating it for the other three quarters, organic designs are much more difficult to achieve. As you may remember from your school days, the geometry of a cube is much simpler than that of a donut (which is actually very advanced geometry). For organic designs, therefore, a wax carving is the better way to go. Additionally, CAD models often have a less intricate and detailed look than wax carving or hand fabrication.

This lack of intricacy can be partly remedied by hand engraving the piece as opposed to adding a pattern to the CAD, and by hand setting it as opposed to adding beads and millgrain to the CAD. This also allows for more variability in the finished piece (i.e. you can set any number of gems into a band or on a shank, as opposed to having to fill the prongs that were already added in the CAD). But as you may have guessed, this increases the price again, as it adds the labor in at another step of the process.

Is there, then, a BEST way to make a piece of jewelry? In my view, no. Cecile Raley Designs is generally very happy with using CAD, but we have also done wax modeling and hand fabrication. One can also mix and match, i.e. cast ring shanks but build the prongs, etc. Making a pendant always involves some simple metalsmithing, as does a post earring, because jump rings and bails or posts have to be soldered on manually after casting. So on the whole, any design house should have all three methods at its disposal, even if it has a preferred way of manufacture.